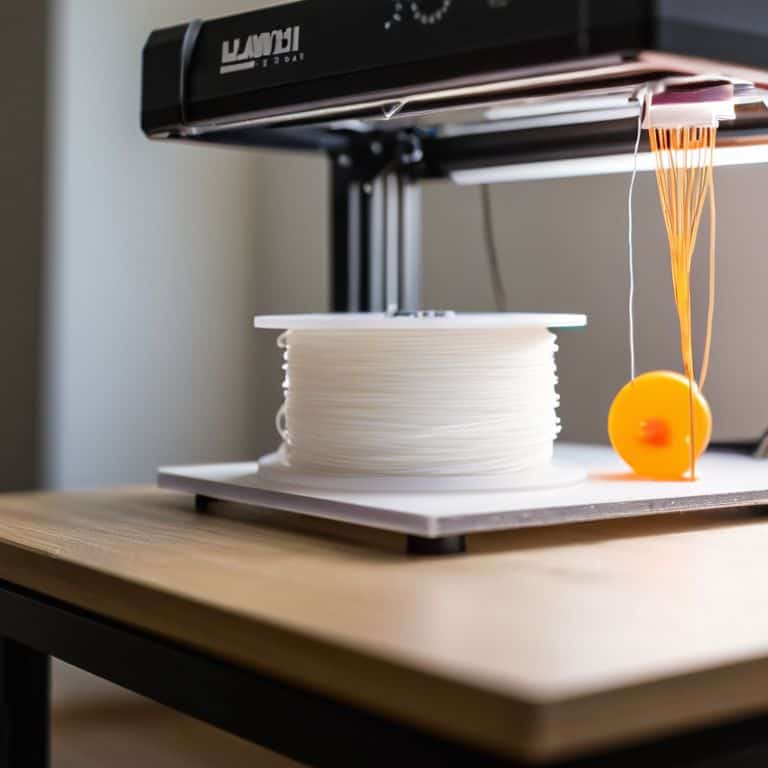

I still remember my first 3D printing project like it was yesterday – I was determined to create a custom phone case, but I was stuck on the what is pla vs abs filament dilemma. I had heard that PLA was more eco-friendly, but ABS was stronger. As a DIY enthusiast, I hated the idea of being limited by the type of filament I chose. I wanted to know the truth behind these two popular types of filament, and I’m sure you do too. After all, making the right choice can make or break your project.

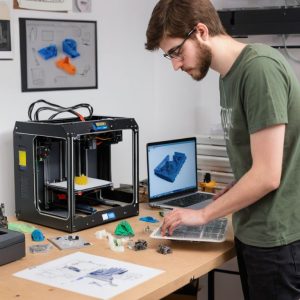

So, if you’re ready to ditch the marketing hype and get a no-nonsense look at PLA and ABS filament, you’re in the right place. In this article, I’ll share my personal experience with both types of filament, including the pros and cons of each. I’ll tell you what worked for me, what didn’t, and what I wish I knew before starting my 3D printing journey. My goal is to empower you to make informed decisions about your projects, and to show you that with the right knowledge, you can achieve amazing results with either PLA or ABS filament.

Table of Contents

PLA Filament

PLA filament is a type of biodegradable thermoplastic made from renewable resources, such as corn starch or sugarcane, with its core mechanism based on melting and solidifying when heated and cooled. Its main selling point is that it’s environmentally friendly and produces minimal warping, making it a popular choice for beginners and experienced makers alike. The PLA vs ABS filament debate often starts with PLA’s unique properties.

I’ve worked with PLA filament on numerous projects, and I can attest that its low melting point makes it a breeze to work with, especially for those new to 3D printing. When I’m building custom gaming PCs or restoring old consoles, I appreciate how PLA filament can be used to create custom parts, such as phone mounts or custom fan grills, that are both functional and visually appealing. The fact that it’s biodegradable is just the icing on the cake, as it aligns with my passion for sustainable tech.

ABS Filament

ABS filament is a type of impact-resistant thermoplastic known for its high durability and resistance to heat, with its core mechanism based on melting and solidifying when heated and cooled, similar to PLA filament. Its main selling point is that it’s incredibly strong and can withstand rough handling, making it a popular choice for creating functional parts and prototypes. When comparing PLA vs ABS filament, ABS’s unique properties often come out on top for certain applications.

I’ve had my fair share of experience with ABS filament, and I can say that its high thermal resistance makes it perfect for creating parts that will be exposed to heat, such as custom phone cases or laptop stands. When I’m working on a project that requires high durability, I often turn to ABS filament, as it can withstand the rough handling that comes with extensive testing. The fact that it’s widely available and affordable makes it a staple in my workshop, and I appreciate its versatility in various DIY projects.

PLA vs ABS Filament: Head-to-Head Comparison

| Feature | PLA | ABS |

|---|---|---|

| Price | $15-$25 per kg | $20-$35 per kg |

| Key Feature | Biodegradable, plant-based | Strong, impact resistant, flexible |

| Best For | Beginners, indoor models, eco-friendly projects | Professional applications, outdoor models, durable parts |

| Temperature Resistance | Low, up to 50°C | High, up to 90°C |

| Warpage | Less prone | More prone |

| Printing Difficulty | Easy | Challenging |

| Environmental Impact | Low, biodegradable | High, non-biodegradable |

Rebel Materials What Is Pla vs Abs Filament

When it comes to rebel materials, the choice between PLA and ABS filament can make or break your project. Understanding the differences is crucial, especially if you’re looking to push the limits of what’s possible with 3D printing.

In a head-to-head comparison, PLA filament is generally more forgiving when it comes to printing conditions, while ABS filament requires more precise temperature control. This means that PLA is often easier to work with, especially for beginners, as it is less prone to warping and can produce smoother finishes.

However, ABS filament has its own advantages, particularly when it comes to durability and impact resistance. ABS prints are often stronger and more resistant to scratches and cracks, making them a better choice for functional parts and high-wear applications.

In conclusion, when it comes to rebel materials, ABS filament is the clear winner due to its superior durability and strength.

Key Takeaways for the Rebel Maker

So, you’ve decided to join the 3D printing revolution – remember, PLA is your go-to for beginner-friendly, low-warp prints, while ABS is the veteran’s choice for high-impact, high-temp applications

Choose your filament like you choose your battles: if you need a strong, durable print that can withstand the elements, ABS might be your new best friend – but don’t say I didn’t warn you about the warping

When in doubt, experiment with both – after all, the best way to learn is by doing, and I’ve got a drawer full of spare parts to prove it: test your prints, push their limits, and join the ranks of the truly DIY

The Rebel's Choice

PLA and ABS filament are like two different mindsets – one’s about ease and simplicity, the other’s about pushing limits and embracing the chaos of creation; which one you choose depends on how much you’re willing to get your hands dirty and challenge the status quo.

Frankie Miller

The Final Verdict: Which Filament Should You Choose?

Now that we’ve dug deep into the world of PLA and ABS filament, it’s time to synthesize our findings. Both types of filament have their own strengths and weaknesses, and the choice between them ultimately depends on your specific needs and preferences. If you’re looking for a more environmentally friendly option, PLA might be the way to go. On the other hand, if you need a filament that can withstand high temperatures and is more impact resistant, ABS could be the better choice.

So, which one should you choose? In my opinion, PLA is the way to go for beginners or those who prioritize ease of use. It’s generally easier to work with and produces less warping, making it perfect for simple prints. On the other hand, ABS is better suited for experienced makers who need a more durable material for their projects. Ultimately, the choice between PLA and ABS filament comes down to your specific needs and goals. By considering the factors we’ve discussed, you can make an informed decision and choose the filament that’s right for you.

Frequently Asked Questions

What are the main differences in printing temperature between PLA and ABS filament?

Alright, let’s talk temperature! PLA typically prints between 190-220°C, while ABS needs a bit more heat, ranging from 220-240°C. Keep in mind, these are general guidelines – your specific printer and project might require some tweaking. Don’t be afraid to experiment and find that sweet spot!

How do PLA and ABS filaments compare in terms of durability and resistance to warping?

Alright, let’s get to the good stuff! PLA and ABS durability-wise, PLA’s more prone to brittleness, while ABS is stronger, but more likely to warp. Think of it like this: PLA’s like a glass vase, ABS is like a rugged toolbox. ABS can handle more stress, but might bend under pressure, whereas PLA’s gonna break if you push it too hard.

Can I use PLA and ABS filaments interchangeably in my 3D printing projects, or are there specific situations where one is preferred over the other?

Not quite, my friend! While both PLA and ABS are popular 3D printing filaments, they’ve got different personalities. PLA is great for beginners, with low warping and a sweet, sweet price point. ABS, on the other hand, is like the tough cousin – more durable, but also more prone to warping. So, choose PLA for decorative pieces or prototypes, and ABS for functional parts that need to withstand some stress.